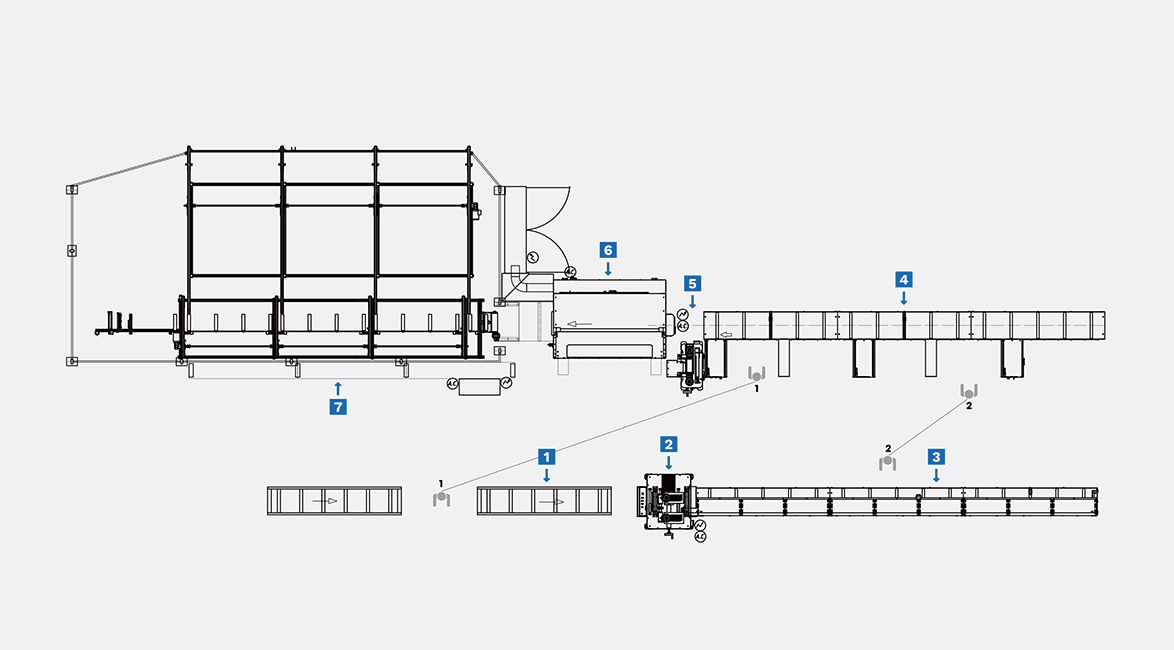

AS 221 GA

Semi-automatic thermal break aluminum extrusion assembly machine

General features

- Rollers that support straight and curved aluminum profiles

- Compensation adjustment rollers

- 8 disc shafts with automatic adjustment

- Front protection barrier and flap door with safety devices

Description

Quick-change upper and lower rollers support straight and curved aluminum profiles, due to their structural flexibility. The upper rollers automatically adjust their position according to any small aluminum profile deformations, thanks to the mechanical and automatic load adjustment. The compensation rollers are adjustable to correct any vertical deformation of the aluminum profile.

The clamping system has eight motorized disc shafts that automatically adjust the closing force of the discs according to any slight deformations of the aluminum profile. Every movement is represented on a digital display.

The front protective barrier and the flap door have opening safety devices. If there is no emergency stop system, the direction of movement can only be changed at low speed.

Spec sheet

- Two-speed three-phase motor: 0.7 – 1.1 Kw – 400 V – 50 Hz

- Front-rear control of the aluminum profile

- Forward speed of the bar: min. 11.1 m/minute – max 22 m/minute

- Each assembly disc has an independent device for fine adjustment.

- You can adjust the position of the vertical guide rollers by using a single control device equipped with a decimal positioner and a pneumatic damper for micro gaps among the profiles.

- The profile twisting correction: +/- 2 mm by an eccentric roller

- Machine overall dimensions (Height x Length x Width): 1410 mm x 1180 mm x 1580

Standard equipment includes:

- Standard polymer lower and upper roller kit for aluminum extrusion profiles’ support and calibration

- Hook-up drawings for each profile

- Manual for installation, operation and maintenance

- Service spanners

Accessories supplied upon request include:

- Kit of assembly discs of your choice

- Special polymer lower and upper roller kit for aluminum extrusion profiles’ support and calibration

- Side aluminum profile support

Browse Certified Pre-Owned Machines

SIMILAR PRODUCTS

LET OUR EXPERTS

EXCEED YOUR EXPECTATIONS

It’s time to experience the difference that buying a machine from a true aluminum expert can make. With our knowledge, approach, and skills, we guarantee to exceed all expectations and blow all competition out of the water.